Search

The CHIRON Group invites to OPEN HOUSE 2025

17th March 2025

“Innovations for future demands – explore our machining world premiere”. This is the motto under which the CHIRON Group welcomes international expert audience to Tuttlingen from 13 to 15 May.

1,500 square meters of exhibition space, twelve machining and turnkey solutions for all user industries in live operation, including a world premiere for micromachining in a new dimension and the dynamic and productive DZ 22 W speed+. In addition, 35 companies in the partner exhibition, a top-class lecture program with topics such as friction stir welding and gear cutting. Plus, presentations from the expertise areas of Services, Automation, Refurbishment and Digital Solutions. The key data for the OPEN HOUSE sound very promising and like a successful new edition of the established format.

World premiere of the new “must have” for micromachining

Here the Micro5 with a workpiece cubature of 50 mm, there the precision model FZ 08 S five axis with 250 mm. And in between? For workpiece cubatures up to 120 mm, the innovation for extended possibilities in demanding machining for medical and precision technology and beyond. Whether bone plates, knee inlays, dental blanks or larger watch cases for chronographs: With the new “must-have”, the CHIRON Group is “scaling up the successful concept in micromachining for new applications,” says Senior Product Manager Michael Wurster. And continues: “More traverse path, higher cutting performance, short cycle times plus the proven advantages such as maximum precision, maximum dynamics and optimum resource efficiency: the small revolution in micromachining that we started a few years ago is now being continued in a logical manner.” What is the name of the new machining center, and how does it relate to the machine's features? The professional audience can find out at the world premiere.

The name says it all: The new DZ 22 W speed+

With a spindle distance of 600 mm, the double-spindle 5-axis machining center DZ 22 W is predestined for the complete machining of large components for series production in various industries. With the DZ 22 W speed+, the CHIRON Group is now presenting a new variant. Thanks to design modifications, the already impressive productivity has been increased by up to 10 percent. Michael Eble, Head of Engineering and responsible for the machine platform, quotes a few key figures: “A 20 percent increase in acceleration, a 40 percent improvement in jerk to reach maximum speed even faster after direction changes. And the new spindle with a ramp-up time of 0.5 seconds and chip-to-chip time of 2.0 seconds: The DZ 22 speed+ is the Formula 1 model of the 22 Series, so to speak. It consistently delivers top speed and brings this advantage safely to the finish line for our customers.”

Requirements and solution perfectly combined – further machine highlights

Plenty of power for precise machining of materials such as Inconel or titanium, combined with corresponding milling performance and dynamics: The FZ 19 S five axis shows how productive even series production can be on a single-spindle machine with a compact footprint. With 700 mm travel in Z, the work area is ideally designed for 5-axis simultaneous machining of both cubic and cylindrical workpieces. Another variant of the Series is shown by experts in the Interactive Showroom: the FZ 19 S mill turn which can also be used for turning applications.

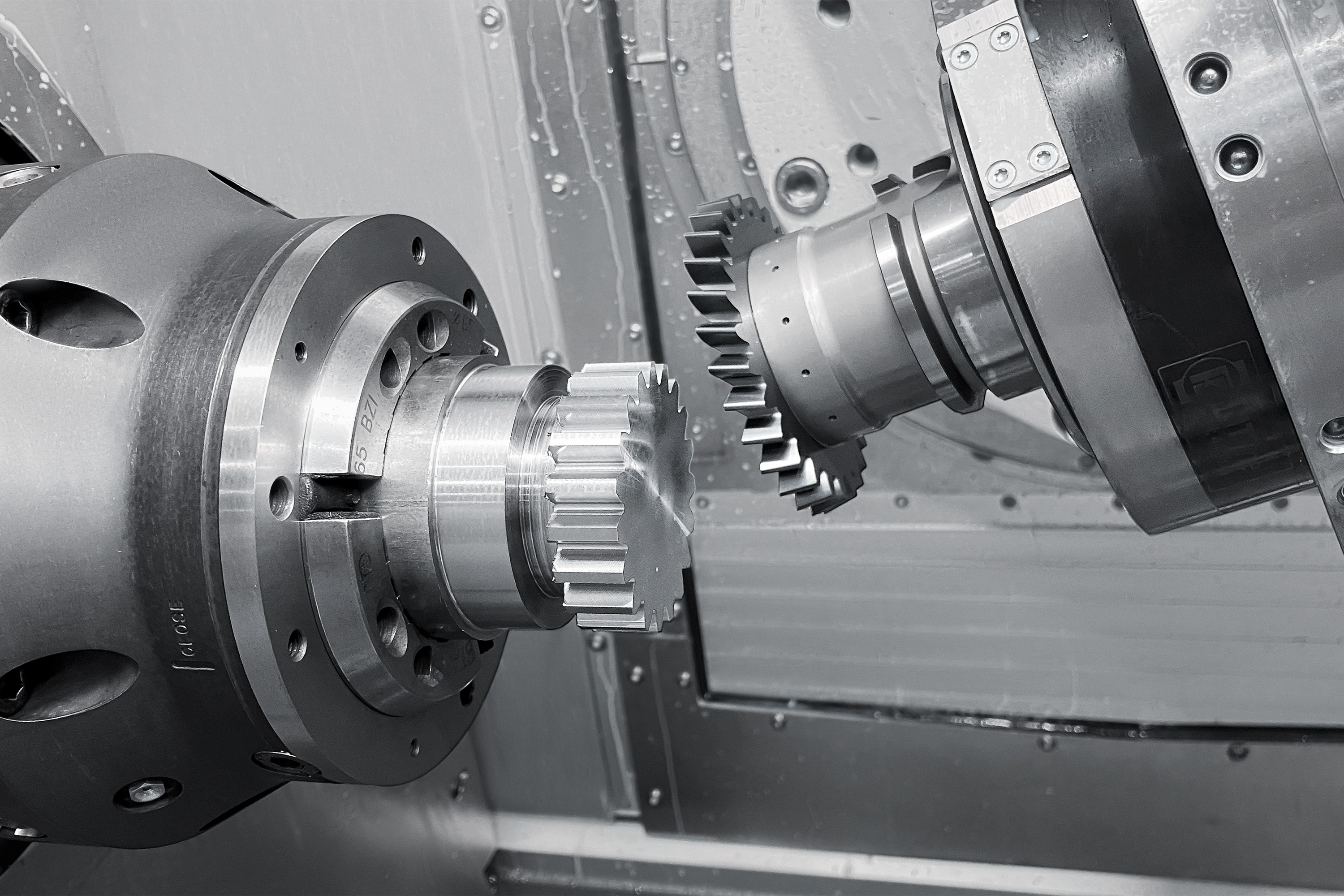

The combination of milling, turning and gear cutting with the MT variants of the 715 Series is also a ‘perfect match’ for requirements such as higher part variance, further optimized workpiece quality and a convincing solution.

All machining operations can be performed on one machine in one clamping position. The result is significantly higher precision, the production processes are leaner and the logistics effort - keyword: parts tourism - is lower.

Precision “on its own account” can be experienced at a special showcase: the FZ 16 S five axis manufactures columns for the Micro5.

Interesting alternatives to buying new

But what if investing in a new machining center is not the top priority at the moment, but the best manufacturing quality is? At the OPEN HOUSE, the CHIRON Group will provide information on several alternatives: a customized refurbishment of an existing machining center, a refurbished machine or PerformanceFinance. The innovative complete package combines top performance – for example with a next-generation machining center from the 15 Series – with IoT analytics and maintenance by the CHIRON Group Service. All this at attractive monthly rates and a short term of 36 or 48 months.

For Matthias Rapp, Vice President Global Marketing, the focus of the event is “of course the presentation of our innovations, but also the intensive, personal exchange. Times are challenging for all players, and our customers have to focus on several goals at the same time. More flexible, more productive, more autonomous, more resilient are just a few keywords. This is exactly what we want to talk about, we want to listen carefully and identify solutions based on the specific requirements. Solutions that are future-proof and contribute to continued success in global competition.”

Register and make an appointment via:

chiron-group.com/news/exhibitions-and-events/chiron-group-open-house-2025

About the CHIRON Group

The CHIRON Group, headquartered in Tuttlingen, is a global company specializing in CNC vertical milling and mill-turn machining centers, as well as turnkey manufacturing solutions. The Group has a global presence, with production and development sites, sales and service subsidiaries, and sales agencies worldwide. Around two thirds of machines and solutions that are sold are exported. Key customer sectors are the automotive, mechanical engineering, medicine and precision engineering, aerospace industries and tool production.

Contact person for editors:

CHIRON Group SE

Melanie Buschle

Kreuzstraße 75, 78532 Tuttlingen, Germany

Phone: +49 (0)7461 940-3255

Mail: [email protected]

www.chiron-group.com